NOVAFLEX?

Novel Materials for Flexible Fuel Cells

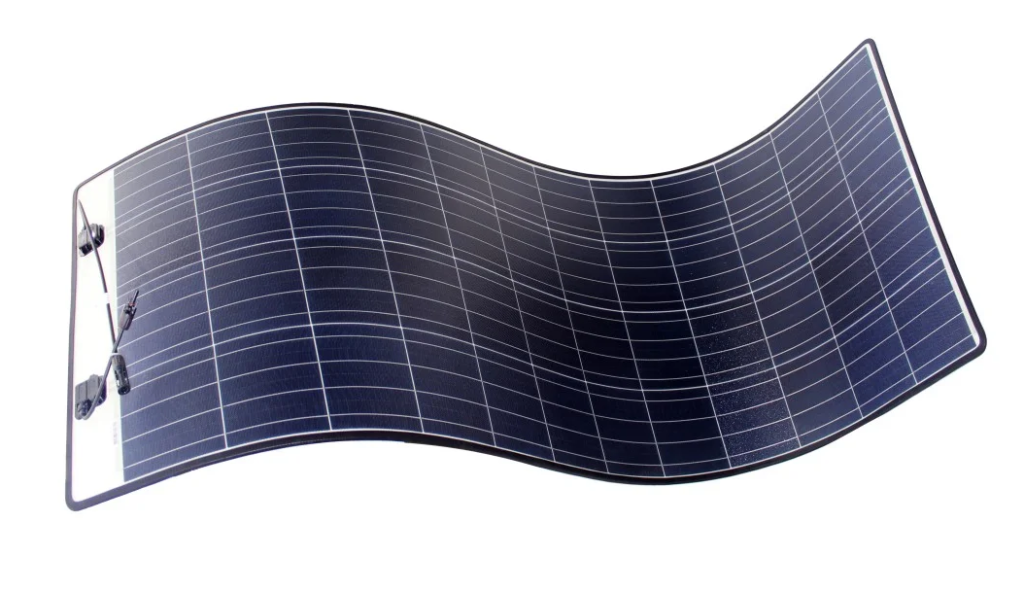

Flexible devices, such as flexible solar cells, flexible lithium batteries, fuel cells and flexible supercapacitors, have been received considerable attention due to a number of advantages including their flexibility, variety of shape, low weight, and excellent mechanical properties. Traditional proton exchange membrane fuel cells (PEMFCs) have a high-energy density, but they are usually heavy, rigid, and awkward. Design, fabrication and refining of a flexible electrode is one of the challenges in the preparation of flexible PEMFCs. This project is aimed at the design and development of technologies for the preparation of efficient anode/cathode catalysts for flexible low temperature PEMFC in order to create lightweight and low-cost fuel cells. The scope of the project is the search, characterization and development of the effective flexible fuel cells membranes with anode/cathode catalysts for PEMFCs. The main tasks are as follows: 1) Fabrication of flexible fuel cells membranes with anode/cathode catalysts by depositing various metal coatings or their foams that have 3D-structure with a high surface area on flexible substrates using electroless and electrochemical metal plating techniques; 2) Fabrication of flexible fuel cells membranes by printing of anode/cathode catalyst inks, such as various metal nanoparticles, reduced graphene oxide on flexible substrates; 3) Investigation of electrocatalytic activity of created anode/cathode catalysts by means of the electrochemical and physicochemical methods; 4) Evaluation of flexible fuel cells parameters, such as cell voltage, power density and efficiency using the created flexible fuel cells membranes with anode/cathode catalysts.

Electricity generated from renewable energy sources (solar, wind, or water) is insufficient to meet growing energy demands. Consequently, the importance and necessity of alternative energy sources, such as fuel cells (FCs) or metal-ion batteries (MIBs), are emphasized. Proton exchange membrane fuel cells (PEMFCs) are an attractive energy source for transportation and portable electronics. Modern PEMFC operation relies on the oxidation of hydrogen or other small organic fuel molecules (e.g., methanol, ethanol) at the anode and oxygen reduction at the cathode. PEMFCs are environmentally clean energy sources since the reaction byproducts are water or water and carbon dioxide. While PEMFCs have a high energy density, traditional designs are typically heavy, rigid, and inconvenient for use in various applications, particularly those requiring flexible forms.

Recently, the search, research, and development of innovative flexible energy sources, such as solar cells, lithium batteries, supercapacitors, and fuel cells, have become increasingly popular.

Flexible PEMFCs can achieve high specific power density with reduced size, volume, and weight, as well as significantly lower costs. The design, fabrication, and optimization of flexible electrodes are among the challenges in developing flexible PEMFCs. Flexible PEMFCs utilize flexible electrodes, including carbon nanotubes (CNTs), graphene, conductive polymers, and Si or Ag nanofibers, which possess high specific surface area and excellent electrical conductivity. It is crucial for flexible PEMFC electrodes to be flexible, stable, and gas-permeable. Moreover, the catalyst deposited on the flexible substrate should exhibit high electrical conductivity and strong adhesion to the substrate.

Contact

- info@sunama-eeagrants.net